UWS Products

Universal Wellhead Services (UWS) provides new and remanufactured products. We have the capability of manufacturing or refurbishing most components in-house for specialty items or emergency basis. We purchase from third-party providers who manufacture all our products to our specific material specifications and machine drawings.

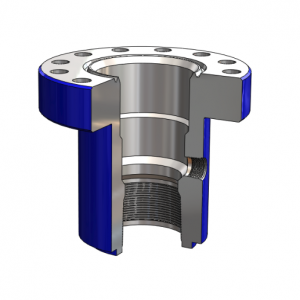

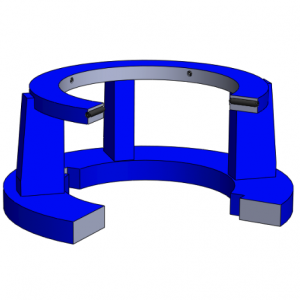

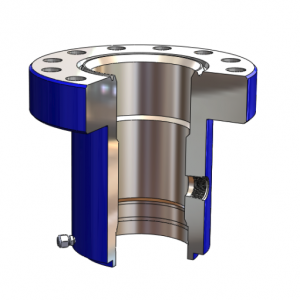

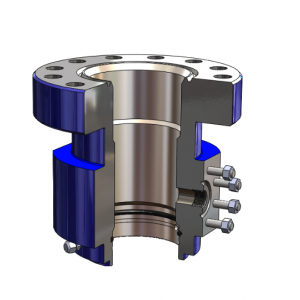

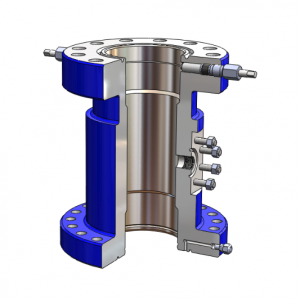

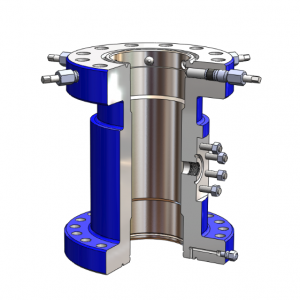

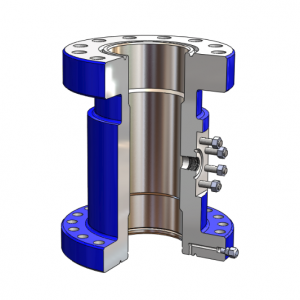

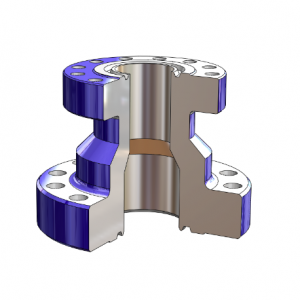

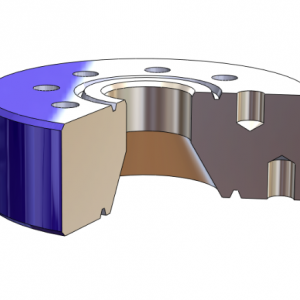

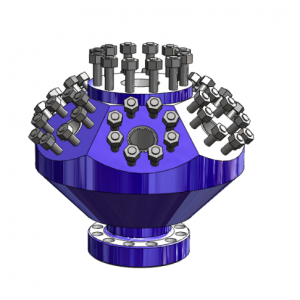

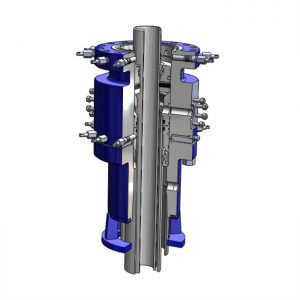

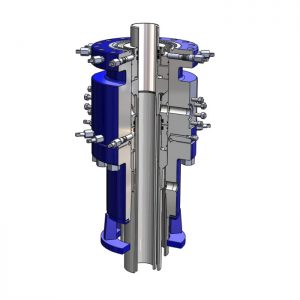

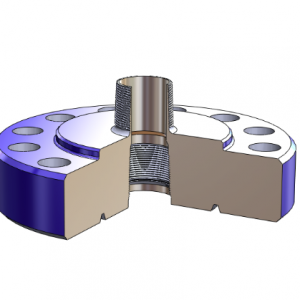

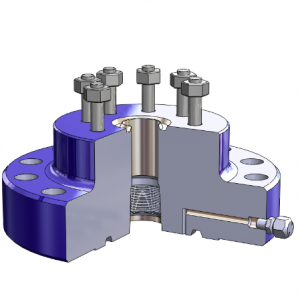

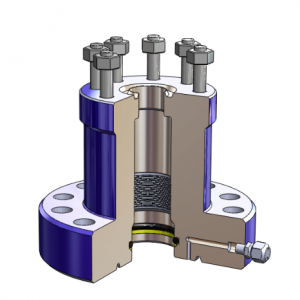

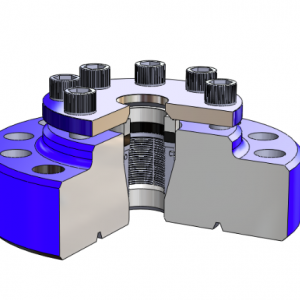

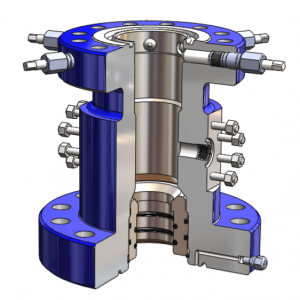

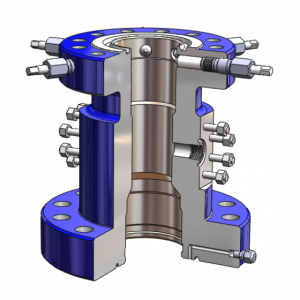

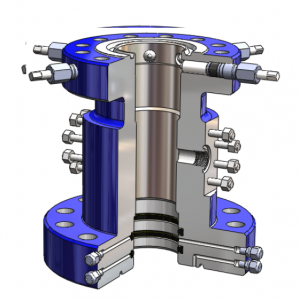

Internal Latch Wellhead System

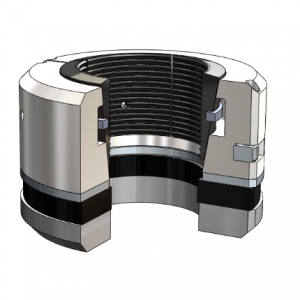

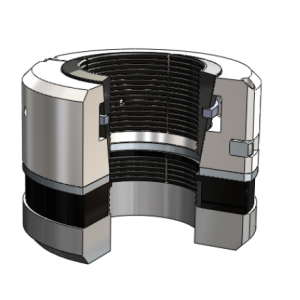

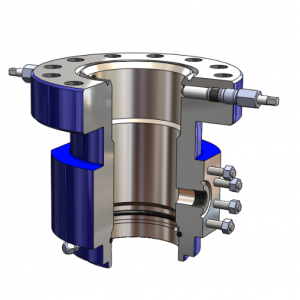

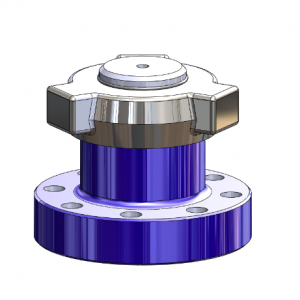

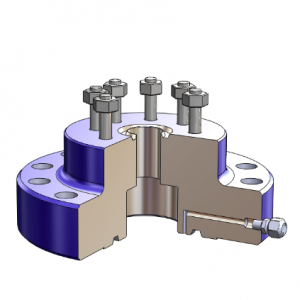

After years of extensive research and development, UWS is proud to introduce our Internal Latch Wellhead System. This system includes three key features and was designed for fast and efficient installation to save valuable rig time while keeping personnel safety a top priority and maximizing the benefits of pad drilling.

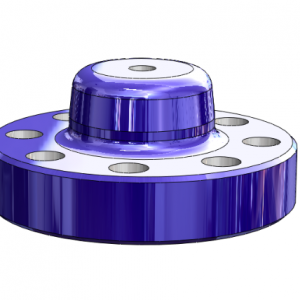

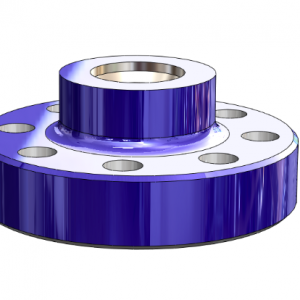

Casing Spools

Consumables

DSA’S, Flanges, Cross-Overs

EFT Systems

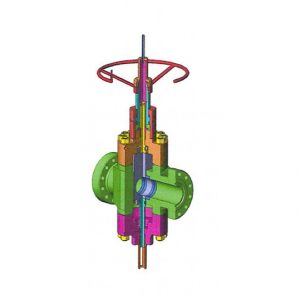

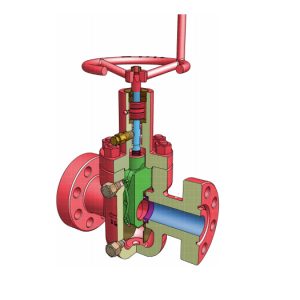

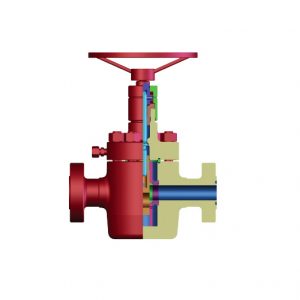

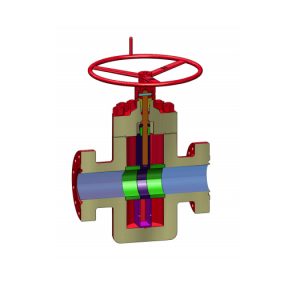

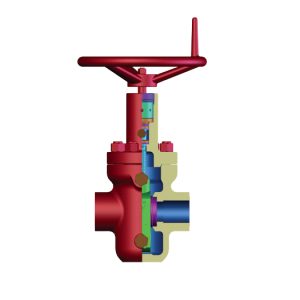

Gate Valves

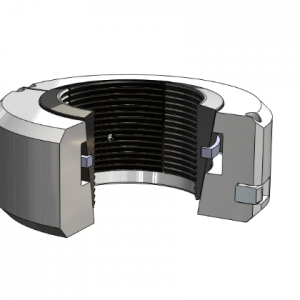

Internal Latch Wellhead System

Safety Valves

Tree Caps, Tees and Crosses

Tubing Head Adapters

Product Assembly Charts

Conventional

Wellhead Chart

Multi-Bowl System

Wellhead Chart

About Our Products

Universal Wellhead Services purchases many of its wellhead and valve components from third-party providers. All of our providers are known to us personally, some for as long as forty years. Each provider we use manufactures all our products to our specific material specifications and machine drawings. We have personally inspected most of their facilities and have reviewed their QA/QC programs.

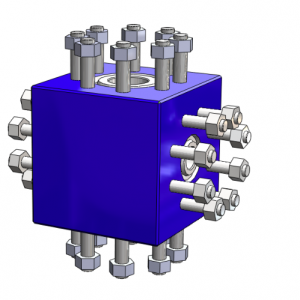

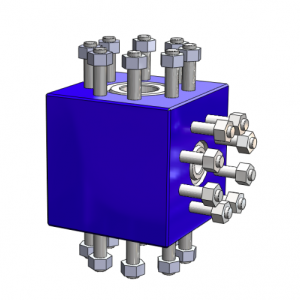

All wellhead components and valves are manufactured to current API-6A specs. We supply the FC and FLS model gate valves for all high pressure applications and for our frac valve use. The FLS valve is the current leader in the valve industry and allows for low operating torque, low pressure sealing, bi-directional installation, metal-to-metal back seating and ease of repair. We offer the Type “M” wedge gate valve profile for lower pressure applications. All frac valves sent to the field will have certifications and test charts. Our wellhead is the C-22 profile, the most widely used in the industry.

Universal Wellhead Services has the capability of manufacturing most components in-house for specialty items or emergency basis, but prefers to purchase from outside sources to provide the best value for our client. We have been able to get excellent deliveries due to our many years of personal relationships we have developed with our providers. Currently, lead time on most sourced components and valves is 90 days from date of order.

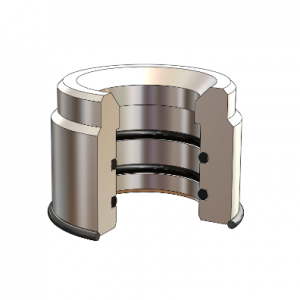

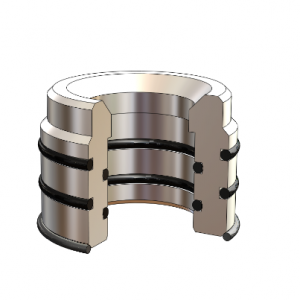

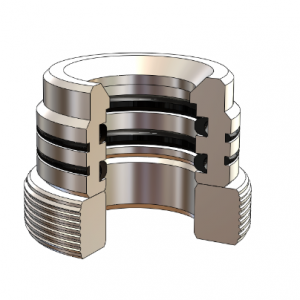

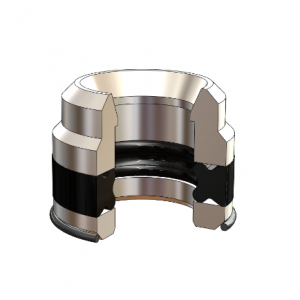

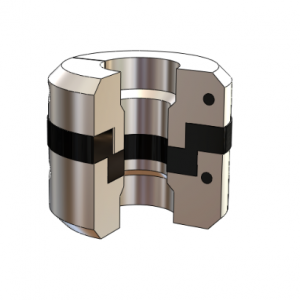

Ancillary products, such as secondary seals, casing hangers, tubing hangers, etc. are purchased from local manufacturers. These products are made to our explicit specifications and drawings. We exceed minimum Elastomers specifications and use HNBR – 80 to 90 durometer material.