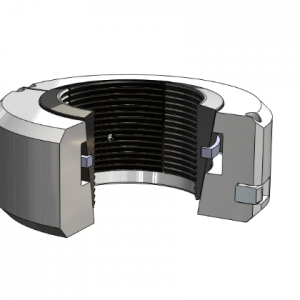

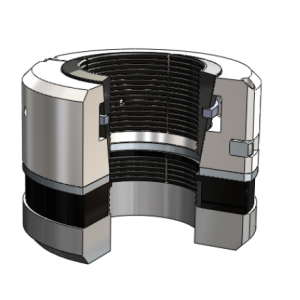

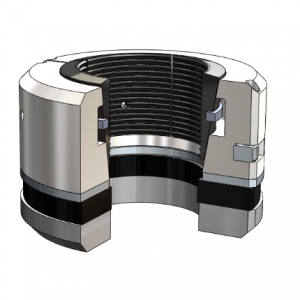

The Casing Hanger is a wellhead component that provides a means to support and seal a casing string. These hangers are a wrap-around style and use slip segments that bite into the casing to support the entire casing load. Our hangers are available in all standard API casing sizes.

Slip Type Hangers

- Supports the casing by transferring the casing load to the load shoulder in the casing head or spool.

- Provides a sealing point around the casing and the casing head bowl to isolate the casing strings.

- Can be lowered through a full opening BOP stack into the wellhead.

- Latch bolt prevents accidental opening of the hanger during installation.

- C-22 and C-29 hangers provide an automatic pack-off seal that is energized by casing weight.

- C-21 hangers are used in conjunction with a separate pack-off plate and are used in low weight situations.

- C-21-P hangers incorporate a built in seal that is manually activated by bolts on top of the hanger

- C-22 hangers require as little as 47,000 pounds of casing load to energize the seal (depends on casing size).

- C-29 hangers have stronger lower support plates and support greater casing loads.

Mandrel Type Hangers

- Supports the casing by transferring the casing load to the load shoulder in the casing head or spool.

- Suspend the casing weight by means of threading the pipe to the lowermost threads in the hanger.

- Lift threads in the top of the hanger are used for landing and retrieving the hanger into the wellhead. ACME threads and a separate running tool can be used in place of the lift threads.

- Optional flutes allow for fluid bypass or taking returns during cementing.

- Separate pack-off bushing- seals around the hanger neck and the wellhead bowl. In the MBS system it also serves to provide another load shoulder to support the next casing string.